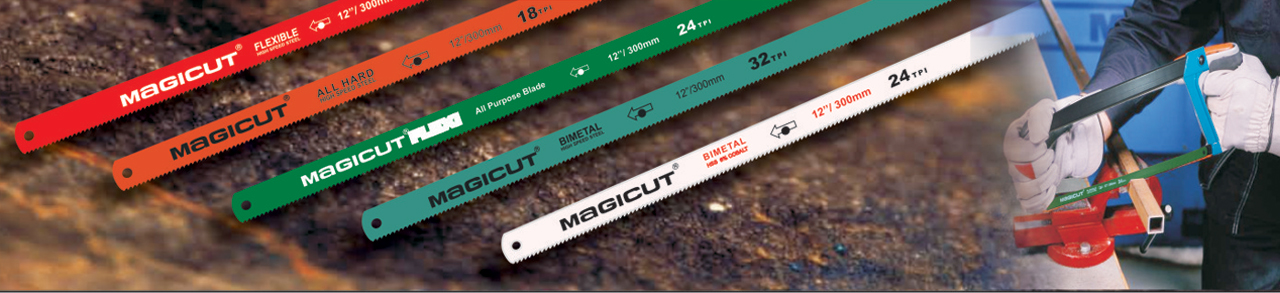

Hand Hacksaw Blades

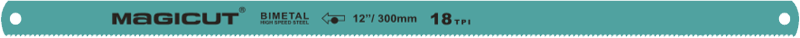

A Virtually unbreakable bimetal blade for superb cutting performance, wear resistance and safety. It combines the toothed high speed steel strip, laser welded to a spring steel back, resulting into a highly flexible blade.

possessing extreme cutting performance that is vastly superior to all hard high speed blades or conventional flexible blades. They cut through all types of materials including alloys and stainless steels.

A Shatter proof blade for high wear resistance as compared to conventional bimetal blades. This has all attributes of bimetal with high alloy 8% cobalt tooth.

The tooth have hardness of 66 to 68 HRC with high wear resistance property. They cut through all types of materials including high alloy steels.

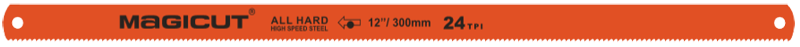

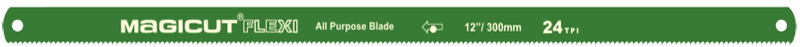

A rigid all hard blade for highly accurate cutting that is ideal for general-purpose work around the workshop.

These blades are uniformly hardened throughout and have a fully hardened back and cutting edge.

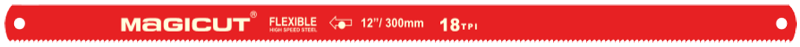

A nearly shatterproof blade with a longer life that is having a hardened edge offering higher flexibility and safety but giving lesser wear resistance than a raditional all hard blade.

High carbon steel blades for all light duty work and are unbreakable in normal condition. They are suitable for all relatively soft materials, such as aluminum, copper, brass, mild steel and other soft metals.

| Size in inches | Size in mm | TPI |

|---|---|---|

| 10 X 1/2 X 0.025 (23G) | 250 X 12.50 X 0.63 | 14,18,24,32 |

| 12 X 1/2 X 0.025 (23G) | 300 X 12.50 X 0.63 | 14,18,24,32 |