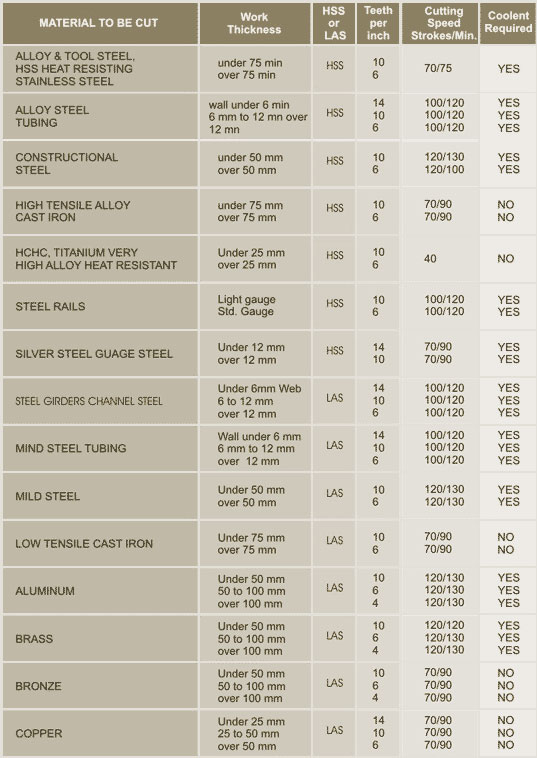

Power Hacksaws Blades Technical Properties

Proper Selection Of Blade

While selecting a blade “Three Teeth Rule” should be followed and this requires that during cutting a minimum of three teeth be continuously in contact with the work.

Thin Sections

Use a fine tooth blade or else metal wedges up between teeth, stripping them off. If the section is too thin to follow, the “Three Teeth Rule” use a very light steady stroke.

Thick Sections

Use a coarse tooth blade with heavy pressure. This gives greater pressure per tooth and consequently a deeper cut. The larger space between teeth gives ample chip clearance.

Hard Sections

Special care must be taken when cutting harder materials. It is better in terms of blade life to use finer tooth blades, with a light pressure and slower speed of cutting or else heat is built up rapidly on the cutting edge causing the metal to soften even in the case of High Speed Steel Blades. Faster speeds are permissible if a coolant is used.

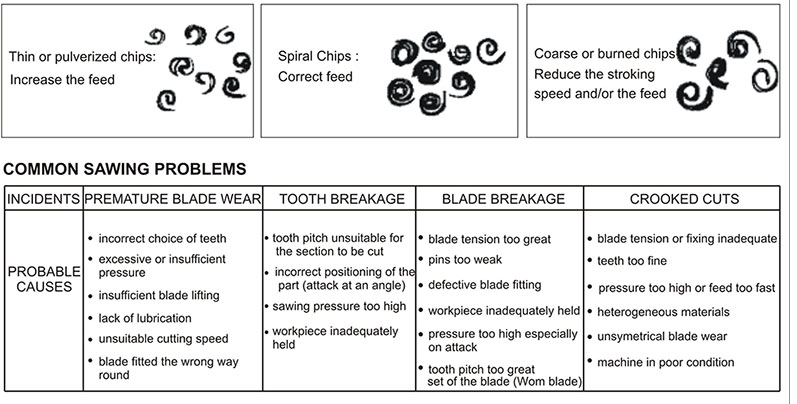

Feed And Chip Form

Be sure that the teeth point away from the handle frame i.e. make certain that they cut on the forward stroke.

- Apply the correct tension to the blade.

- When sharp angles or else the “ Three Teeth Rule” is violated for any blade used.

- Start the cut with the blade at a slight angle and with light pressure gradually increasing the pressure as more teeth come in contact with the job.

- If very thin section are to be cut, clamp them between two pieces of wood and cut as a whole.

- For low alloy hand blades, the speed of cutting should be approximately 55 strokes/ min.

- For High Speed Steel hand baldes, use a higher speed approximately 65 strokes/min expect when cutting tool steel, in which case the speed should never exceed 40 strokes/min.

- After starting the machine, lower the frame carefully and relieve the weight (or reduce the feed) for a few strokes. After cutting the first two or three sections check that the tension is correct.